Heavy-duty Equipment

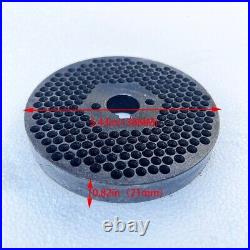

Heavy-duty Feed Pellet Mill Machine 4&6mm Plant Equipment Pellets 220V(Green) US

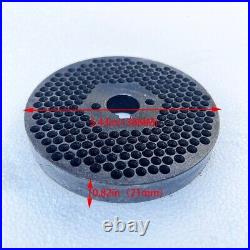

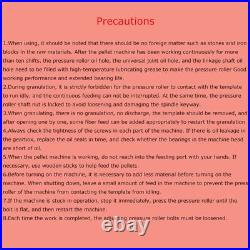

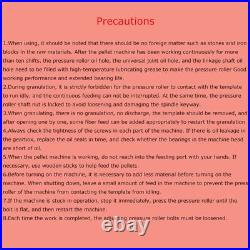

Feed Pellet Mill Machine Granulator Movable Feed Making Machine 220V Powered Farm Animal Pellet Mill Machine 3 Heads Pellet Fodder Press Pelletizer with 4mm&6mm Disc Plate 440LBS/H Feed Pellet Maker Machine for Animal Feeding Movable Plant Equipment Pellets. It is widely used in feed production workshops, breeding farms, zoos, etc. It can quickly produce various feed pellets for chickens, ducks, sheep, cattle and other animals, saving a lot of time and manpower. The machine can freely match different sizes of pressure plate, there are 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm 8 sizes for your choice. But 10mm and 12mm need to be customized. Many different size plates for choosing if you need, but the machine just has 4mm and 6mm dis plate with it. You could get 4mm and 6mm different size feed pellet just through changing the disc plate. 2mm: Suitable for parrot, thrush, sparrow, indigo and other pet birds. 3mm: Suitable for baby rabbits, baby chickens, baby ducks, pigeons, grass carp and other small animals. 4mm: Suitable for adult rabbits, chickens, ducks, geese, pigeons, peacocks, etc. 5mm&6mm&7mm: Suitable for pigs, cattle, sheep, dogs, etc. 8mm&10mm&12mm: Suitable for fishing lures, large birds, large animals, etc. 150kg/h-200kg/h(330LBS/H-440LBS/H) if you choose. Farms, feed mills etc. Iron or stones cannot be put into the griller. Checking the elasticity of the belt, and the bearing frequently. Add oil in time when it needs to. It can’t use wood and plastic. Metal Body & Detachable Feed Hopper & 3 Head Pressure Roller. The machine is made of metal material, which is sturdy and durable. And equipped with moving wheels, easy to move. The feeding hopper can be disassembled for easy cleaning. 3 roller pressing shaft, the effect is better. And the output is larger and the output capacity is more sufficient. The feeding port of the machine is equipped with a pressure screw, and the corresponding pressure can be selected according to the hardness of the material, which is convenient for adjustment, and at the same time, the machine can better act on materials of different hardness and produce feed pellets of different materials. The machine with 4mm and 6mm grinding disc, which can produce large pellets of feed, suitable for feeding adult animals. If you want to choose another size platen, please first remove the feed hopper, pressure screw and 3-head pressure roller, loosen the fixing screw in the middle, remove the original grinding plate smoothly, replace it with a new one, and assemble it back. Wide Range of Use. It is suitable for the production of feed pellets for pigs, dogs, sheep, cattle and large birds. Widely used in feed factories, farms, zoos, ranches, etc. One machine is multi-purpose and has a wide range of use, saving manpower and material resources. When using, it should be noted that there should be no foreign matter such as stones and ironblocks in the raw materials. After the pellet machine has been working continuously for morethan ten shifts, the pressure roller oil hole, the universal joint oil hole, and the linkage shaft oilhole need to be filled with high-temperature lubricating grease to make the pressure roller Goodworking performance and extended bearing life. When granulating, there is no granulation, no discharge, the template should be removed, andafter opening one by one, some fiber feed can be added appropriately to restart the granulation. Always check the tightness of the screws in each part of the machine. If there is oil leakage inthe gearbox, replace the oil seals in time, and check whether the bearings in the machine headare short of oil. When the pellet machine is working, do not reach into the feeding port with your hands. If necessary, use wooden sticks to help feed the pellets. Before turning on the machine, it is necessary to add less material before turning on the machine. Ount of feed in the machine to prevent the pressroller of the machine from contacting the template from idling. If the machine is stuck in operation, stop it immediately, press the pressure roller until thebolt is flat, and then restart the machine. Each time the work is completed, the adjusting pressure roller bolts must be loosened. Failure Analysis And Solutions. When the machine is turned on, the die hole is blocked and no particles can be obtained. Flat die hole corrosion. Remove the residual particles in the die hole. The flat die hole is corroded and the finish is poor. Grinding with high oil content powder. The gap between the template and the pressure roller is too large. Adjust the gap at 0.1-0.3mm. The particles contain excessive powder or do not form particles. The moisture content of the powder is too low. The moisture content of the powder is too high. The powder contains a large amount of crude fiber. Increase the viscous powder. The output capacity gradually decreases. The gap between the die and the roll is too large. Adjust the die roll gap. The moisture content is too low. Increase the water content. The particles are hard and shiny. Powder moisture content is low. Increase the moisture content of the powder. The particles become soft and the surface develops rough. Increase or decrease water content. Initial use of the new template. Grind the machine repeatedly. The pellet machine suddenly does not work. There is a large hard object or metal entering between the die rolls. Check the circuit voltage. Steps for Changing Disc Plate. 1Feed Pellet Mill Machine 220V 4.5KW Powered Pellet Mill Making Machine with 4mm&6mm Disc Plate(239202+239549). Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item.

Heavy-duty Texture Spraying Equipment Sprayer Used in Ships Bridges Tower Poles

Designed in the design of filters, easy to replace, it is possible to filter the paint to reduce nozzle clogging. Ergonomic handle designed to reduce fatigue. Fast, easy to clean, easy to use, excellent atomization. Airless spray gun is perfect for varnishing and dispersion paints. Specification: Material:Stainless Steel + Aluminum Type:Bare Spraying Machine/3-piece Set(Optional) Mixed Size Package Includes: 1 Set High Pressure Airless Putty Spraying Machine note: The real color of the item may be slightly different from the pictures shown on website caused by many factors such as brightness of your monitor and light brightness. Please allow slight manual measurement deviation for the data.

Heavy-duty Texture Equipment Sprayer Used in Ships Bridges Tower Poles

Designed in the design of filters, easy to replace, it is possible to filter the paint to reduce nozzle clogging. Ergonomic handle designed to reduce fatigue. Fast, easy to clean, easy to use, excellent atomization. Airless is perfect for varnishing and dispersion paints. Specifications: Material:Stainless Steel + Aluminum Type:Bare Machine/3-piece Set(Optional) Mixed Size Package Includes: 1 Set Pressure Airless Putty Machine note: The real color of the item may be slightly different from the pictures shown on website caused by many factors such as brightness of your monitor and light brightness. Please allow slight manual measurement deviation for the data.

Heavy-duty Texture Spraying Equipment Sprayer Used in Ships Bridges Tower Poles

Designed in the design of filters, easy to replace, it is possible to filter the paint to reduce nozzle clogging. Ergonomic handle designed to reduce fatigue. Fast, easy to clean, easy to use, excellent atomization. Airless is perfect for varnishing and dispersion paints. Specifications: Material:Stainless Steel + Aluminum Type:Bare Spraying Machine/3-piece Set(Optional) Mixed Size Package Includes: 1 Set High Pressure Airless Putty Spraying Machine note: The real color of the item may be slightly different from the pictures shown on website caused by many factors such as brightness of your monitor and light brightness. Please allow slight manual measurement deviation for the data.